8th June 2022

8th June 2022

For Marches Biogas, Health and Safety is always our first consideration, ensuring the safety of our clients, operators and our own staff in all things we do. We are passionate about the world of AD but we are always very conscious that hazards are all around us from deep tanks to poisonous gases. What’s more not only are these hazards life threatening but the rules around them are also complex.

In Marches we are always striving to keep abreast of everything that’s going on in our industry and to ensure best practice. As awareness of AD and it’s many benefits grows, there will also likely to be an increase in the need for ensuring thorough certification and recorded maintenance of all AD plants. Here in the UK all AD plants need to comply with the Dangerous Substances and Explosive Atmospheres Regulations (DSEAR). AD facilities must have undertaken a formal review of where it is likely that explosive atmospheres may be present, whether this is continually, occasionally or rarely. The identified zones must be clearly marked on drawings and in additional risk based consideration must be recorded to justify and support the hazardous areas.

Identified hazardous areas must also be clearly identified with suitable signage. Ideally no electrical equipment should be located within these zones however if this is unavoidable then only equipment that has been appropriately classified as safe for use within the hazardous area identified should be installed.

In addition to routine mechanical and electrical maintenance, inspection of biogas and certified equipment should also be undertaken and formally recorded. The inspections should include confirmation of the integrity of the existing installation, review of all safety related devices, an inspection of all equipment glanding to ensure that the glands are correct for the zone and also to ensure that any new equipment installed in the zones is suitably rated for the environment.

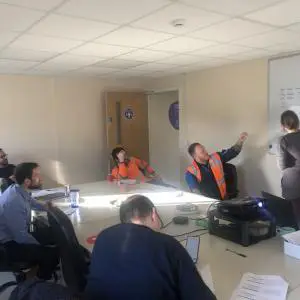

Both mechanical and electrical inspections of equipment located in these zones should be undertaken using competent and qualified CompEx engineers. For those of you who aren’t as familiar with this qualification, this is a global certification scheme for electrical and mechanical crafts persons and designers working in potentially explosive atmospheres.

One of the many complications now evident as a result of Brexit is the interpretation and compliance to recognized safety standards. There always were different interpretations of EU directives leading to slightly different regulations in each member state. However, now the UK has gone its own way certain EU member states that import AD equipment are now working to different regs to those that operate here in the UK. As a result of this, we are aware that some of the formal documentation previously provided by European technology providers is now being questioned as unsuitable. This is a complicated area! Furthermore, recent findings into biogas production in raw food waste and raw sludge cake and sludges are now changing many historic design assumptions regarding hazardous area zoning, which will lead to major health and safety implications. If you want further insight into some of these findings then head over to our case studies page to read more about silo headspace safety concerns.

So if you have a niggle in the back of your mind that something might not be right or you just want some piece of mind knowing that you are on the right track, please do give Marches a call and our technical folk will be happy to discuss the complexities of DSEAR and CompEx and put you on the straight and narrow.

More Articles

Energy costs and importance of maintenance

As we are all aware energy costs are rising and the world continues to be a strange place; in fact, this winters power prices…

15th July 2022

Devoted blog readers will know that we all love working at Marches Biogas and within the anaerobic digestion business in…

19th April 2022

Most people acknowledge that it’s difficult to evaluate the value of training, how do you know when you send people…

3rd March 2022

So, if you have been following our blog, you will know that Marches are currently building more AD plants and have a number…