Energy costs and importance of maintenance

As we are all aware energy costs are rising and the world continues to be a strange place; in fact, this winters power prices…

The Marches Biogas blog provides interesting insights into the characters within the company and explores current AD and biogas industry topics.

As we are all aware energy costs are rising and the world continues to be a strange place; in fact, this winters power prices…

Devoted blog readers will know that we all love working at Marches Biogas and within the anaerobic digestion business in…

For Marches Biogas, Health and Safety is always our first consideration, ensuring the safety of our clients, operators and…

Most people acknowledge that it’s difficult to evaluate the value of training, how do you know when you send people…

So, if you have been following our blog, you will know that Marches are currently building more AD plants and have a number…

Marches Biogas have built a lot of AD plants; hopefully this is not a big surprise to our loyal readership, our reputation…

The AD year is relentlessly following its path with the days getting shorter at an alarming rate. The agricultural based…

In the past we have spoken at length about mixing systems and the importance of keeping your tanks in good order. However…

As those of you dedicated followers of Marches will know, we have built a few tanks in our time, large ones, small ones, …

Normally when you have a manufacturing plant the by-products produced can be a problem; what to do with them? How do you…

We all know the future can be a scary space, recent world events have been a reminder of this and sometimes it’s difficult…

It’s time to mention some of the heroes behind the organisation that do not always take the limelight but are vital…

As a part of this blog, we try to shed some light on some of the characters that make up the wider community of Marches …

'Does exactly what it says on the tin' is a phrase that everybody understands and pretty…

As you know as an avid reader of this blog (and numbers are growing!) we at Marches Biogas spend a lot of time designing…

There are loads of fascinating and interesting things about running a waste AD plant; thinking about all the tonnes of landfill…

One of the cool things about working for Marches Biogas is the innovation in design that the company has given the industry…

In this economic uncertainty decisions about the future can be difficult to make, especially when its committing …

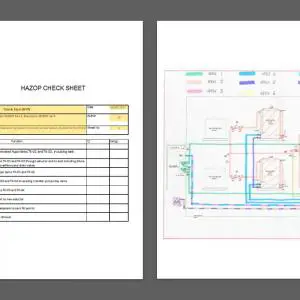

So we need to have a chat about HAZOP. It's one of those phrases that is thrown about the industry especially when you are…

In the world of AD there are lots of people who are very happy to tell you what to do, but there are fewer who can show …

At Marches we have a healthy respect for the dangers we all face, in fact it’s because we have been doing this for…

When I first joined an AD company a long time ago I heard frequent reference to tea; it came from hushed voices round the…

So here we are in a rather cold and wet part of Shropshire, the only evidence for our past over-indulgences being a slightly…

As December marches forwards to 2021 and we say goodbye to the enigma that has been 2020, we have a time to contemplate …

Optimism – it’s an easy word to say but in these ‘interesting times’ (as people keep calling 2020…

We have some brilliant news, that we have signed our first major international project! Now, Marches Biogas benefits from…

Having just done a piece on Keith it is only fair to do one on Mark (and to let you in on a little secret they both hate…

We thought it might be a good idea to use this blog to introduce some of the characters behind the Marches Biogas curtain…

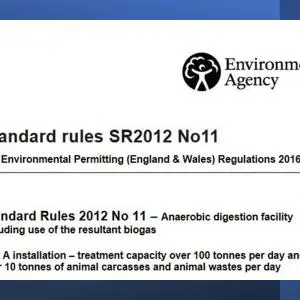

So here’s an early warning; this blog is about engineering standards. When Keith and Mark suggested the topic a sharp…

In this blog we want to talk a little about the maintenance side of the business, what was once known as Evolution Biogas…

In this blog I want to talk a little about the company structure. As the astute observer to Marches Biogas will know…

The beauty of having a diverse team is people are always coming up with new ideas. Some sound great at first listening and…

So in February the Covid-19 storm hit the UK, which meant lots of changes in the way we all go about our daily lives. The…

In this blog we want to talk a little about the changes in support that the AD industry has received over the last decade…

The second edition; that tricky second album…. So for this edition of the blog we want to talk about how Marches …

This is a new blog to talk about life (and of course anaerobic digestion!) in and around Marches Biogas. We want to talk…